Firstly, I must offer my grateful thanks to Kathryn Jones (Senior Curator of Decorative Arts), Karen Lawson (Images and rights manager) and the team at the Royal Collection Trust who have so generously allowed me to use my photographic images of the Needwood Forest torc – in publications and online – without charge.

This is a really progressive and enlightened decision and will allow the ongoing research into this torc to be open access, and shared. It makes such a big difference to be able to use any – and all – images needed to document and demonstrate the making of this torc: if only all institutions could have such open-handed and case-specific policies. Well done to the RCT!

But back to the Needwood Forest torc (Fig. 1), which, the more I study it, becomes increasingly fascinating and important! If you need to remind yourself of the historical and archaeological evidence for this torc, this can be found in Part 6.

Wires

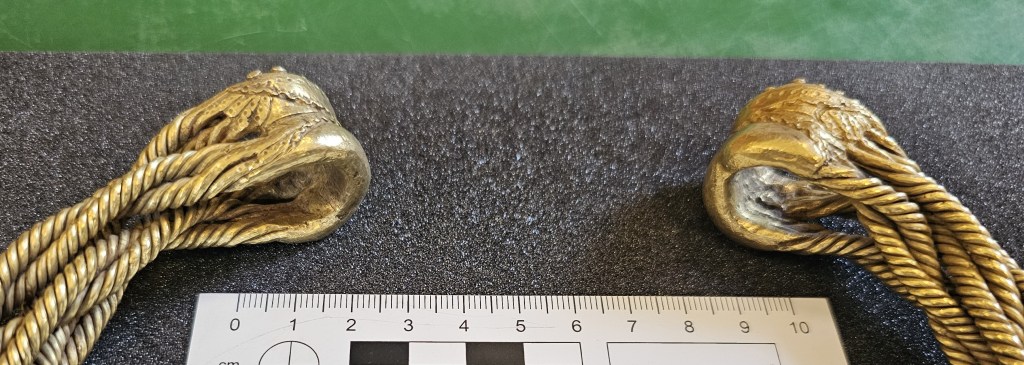

The torc comprises thirty-two wires, which have been coiled into eight coils of four (or possibly occassionally three) wires each. These eight coils have then been twisted – in pairs – into four ropes and then these four ropes have been loosely twisted into a neck ring (Fig. 2).

The neck ring has then had two, u-shaped, terminals created, with a rope of two paired-coils at each of the four ‘corners’ of the terminals. When you pick the torc up, it feels flexible, but does have a rigidity in its form. It would not have lost shape, but would have been flexible enough to put on and take off easily.

The torc has an internal diameter of c.140mm by 130mm and an external diameter of c. 180mm by 175mm. As such it is certainly of dimensions suitable to have been worn on the neck. The torc weighs 427g.

The neck ring is between c. 16.3mm and 17.8mm thick and each coil of wires is between c.3.5mm and 4.2mm in thickness. Each wire in each coil measures between 1.3mm and 1.6mm in thickness and the wires are, on the whole, even. The wires are hammered but in places show evidence of lamination (Fig. 3) in the gold alloy suggesting the wires have been insufficiently annealed during the making or that the original ingot the wire was hammered out of was badly poured (if any goldsmiths have thoughts of how this can occur, I would love to hear them).

On the back of the torc (Fig. 1: top left of image), one of the wires in the neck ring is quite badly distorted (Fig. 4). This would appear to have occurred during the wire making process. It seems that the wire was not fully rounded in this section – perhaps the goldsmith realised there was a flaw in this section and so did not fully work the wire into the round so as to preserve the wire integrity? or the wire may have become misshapen and split during the coil twisting due to a variation or flaw in the gold alloy? [Edit: Hamish Bowie has suggested that this, like the configuration seen in Fig.5, could be evidence of wires being spliced together, although the splitting of the wire during working still seems likely].

A further point of interest is an apparent break in the wires on the upper right of the front side of the torc (Figs. 1: top right of image & 5). This break appears to have occurred during the coiling of the wires and it would seem that the broken ends of the wire have been tucked into the coil to secure them, or that a break has been spliced with new wire. A later repair of a break is possible, although this seems unlikely in a coiled neck ring, where stress would be widely distributed across the neck ring.

Terminals

The terminals of this torc, although apparently similar, are slightly different, most notably in the number of dummy rivets on the terminal sides: Terminal 1 has nine dummy rivets, and Terminal 2, thirteen (Fig. 6).

Terminal 1 has an internal diameter of c.17.5mm, and an external diameter of c.24.2mm and is c.6mm thick at the edge. Terminal 2 has an internal diameter of c.16.7mm, an external diameter of c.24.3mm and is around 5.9mm thick at the edge. Both terminals are thinner away from the edge.

The terminals of this torc are roughly finished, with evidence of bubbles on the interior surface (Fig. 7). There is irregularity in the terminals with some faces of the terminals showing as more ‘complete’ (see Fig. 13: middle) and others showing a pronounced gap along the line of the fused paired coils (see Fig. 12: middle)

Discussions with Bob Davies have suggested that the terminals are likely to have been created by fusing the wire ropes together before then hammering and punching the cooled fused wires into shape.

The first stage in this process would be to create ropes long enough to allow for looped ends to the neck ring. These wire loops would then be heated to a semi-molten state, which would fuse the wires together into a rough u-shape (perhaps with the addition of some alloy to fill in gaps).

The terminals were cooled and then hammered and punched on the exterior to create definition and detail. The bubbles on the interior are the only remnant of the making with the similar width of the terminals to the wire ropes (Fig. 8) betraying their probable wire rope origins. The fusing theory would explain both the irregular shape of the terminals and the differing number, and size, of the dummy rivets as alloy would be unevenly distributed in a fusing process.

There is evidence of hammering/punching all over the terminals (Fig. 9) and it would appear that the dummy rivets have been under-cut around the base of each rivet to create their 3D shape (Fig. 10). This method is typical of other gold torcs (for example, Newark and Netherurd) of the period, although these are sheet gold examples.

Decoration

As previously noted, the terminals are decorated with dummy rivets. They are of irregular sizes between c.1.5mm to 3mm and occur only on the external face of the torc terminals (Figs. 6 & 10), with the internal face left blank (Fig. 11).

Unlike dummy rivets on other torcs (for example the Snettisham Great, Newark and Sedgeford torcs and the Netherurd and Near Stowmarket terminals) the Needwood Forest dummy rivets do not have triple or single dots punched into their surfaces.

There are other torcs with unpunched dummy rivets: the Clevedon terminal, and the – perhaps unfinished – Ipswich and North Creake torcs and terminal providing other examples similar to the Needwood Forest dummy rivets. The crescent of dummy rivets echoes those seen on the Hengistbury Head terminal and, as a complete circle, on the Netherurd terminal and Knaresborough ring.

There is no sign of ‘nicking’ or any other secondary modification of the torc.

The rest of the terminal decoration comprises punched dots, lines and rick-rack/wavy lines (Figs. 12 & 13). The decoration of the terminals is laid out as follows: on each terminal there are two crescent shaped, rick-rack/wavy lines which start at each terminal ‘corner’ and converge in the centre of the terminal. These lines have been created by first punching/chiselling two parallel lines, to leave a raised line between. Alternate dots have then been punched on each side of this raised line to create the rick-rack/wavy line effect.

On the front of each terminal, and behind the raised dummy rivets, there is a punched/chiselled line which goes around the face of the torc. Behind this line is a row of punched dots of c.0.7mm to 1mm in diameter. The lines appear to have a v-shaped, rather than a rounded u-shaped profile and so it is likely that a v-shaped punch/chisel, rather than a round-ended punch, was used to create this, and other, lines on the terminals. However, to create the punched dots – which have a smooth, curved, profile – a round-ended punch would have been used.

On each side of the terminal, starting where the wires meet the terminal, are punched/chiselled lines, which are aligned to roughly follow, and extend, the trajectory of the neck ring wires into the terminal. Between pairs of these lines are a number of closely spaced punched dots.

On the front and back of Terminal 1 and on the back of Terminal 2, there is a lozenge shaped area (defined by a punched/chiselled line) which is then bisected by a single line which continues to meet the two converging rick-rack/wavy lines (Figs. 12 & 13). The exception to this is the front of Terminal 2 (Fig. 13: left), where the punched lines and dots continue up to meet the rick-rack/wavy line, and there is no lozenge present.

The work appears to have been completed with confidence and speed (there is little evidence of double-punched dots or lines being scribed twice), albeit in a rather free-form manner. The preciseness and uniformity of decoration seen on, for example, the Snettisham Great or Sedgeford torcs is not present (Fig. 14)

Significance of the decoration

The decoration of the Needwood Forest torc conforms to styles and motifs seen in many other gold alloy Iron Age ‘Snettisham Style’ torcs. In a recent paper we have suggested that punched dots and rick-rack/way lines should be included in the Snettisham decorative suite and the Needwood Forest torc again reinforces this suggestion.

Again, as in the Snettisham Great torc, the South West Norfolk torc and in several other Snettisham torcs (see Table 1 here) the rick-rack decorative lines of the Needwood Forest torc appear to be marking out hidden joins in the alloy beneath, between the paired ropes in this case. This can also be seen in the parallel lines of the Needwood Forest decoration, which echo the position of the wires, fused into the torc terminal.

The punched/chiselled lines and line of punched dots around the terminal edges again echo several other Iron Age torcs, most obviously the Snettisham Great torc, the Netherurd terminal and Newark torc, which all have lines of punched dots behind their terminal faces (Fig. 15).

There is also a similarity to other torcs, such as 1991,0407.34 and 1991,0407.22 from Hoard H at Snettisham, the South West Norfolk torc and the Glascote torc, with lines of punched dots or rick-rack marking out technical joins or wires hidden in the alloy beneath (Fig. 16). This torc brings me onto another idea that’s been developing during the course of researching and writing these blogs: I’ve changed my mind on something I wrote about in Part 8 of this Odyssey!

Then I thought we were always looking at terminals which had gold alloy added/overcast to create the terminals but now, having seen Needwood Forest up close and having talked it through with others, although rough overcasting is still possible, I am erring towards the idea that torcs such as Needwood Forest, the Snettisham torcs 1991,0407.34 and 1991,0407.22 , and possibly even Glascote (Fig. 16), do not have gold alloy added to create the terminals, but were instead created from the fused wires of the neck ring. Further examination of these torcs will be necessary to confirm or deny this.

Final thoughts

The Needwood Forest torc is competent and cleverly achieved, however, close up it is very rough and ready, although apparently achieved with a quickness and confidence of skill. As mentioned in Part 10 of this Odyssey blog, when you get up close with lots of torcs you start to get a feeling for the individual makers and their styles: what would be called ‘connoisseurship’ in art history circles.

The concept of connoisseurship is now largely discredited as an idea that largely favours male-dominated class privilege, but I do think it bears thinking about in the context of gold research. There is certainly a knowledge and understanding beyond that accurately definable in words when looking at – and talking about – torcs .

For me, you get a feeling about a torc and the way it’s been worked, which then often bears out only later in hard data and evidence. In the case of the Needwood Forest torc, the torc this most closely reminded me of was the Netherurd terminal: the movement, confidence, overall beauty – but irregularity and lack of order when viewed up close. There is also a great similarity in the planishing/ hammering across the terminal surfaces of Needwood Forest (Fig. 9) to that seen in the Netherurd and Newark torcs. Could Needwood Forest be related to these two other, known to be related, torcs? Although difficult to confirm at present, it is worth keeping in mind.

The other interesting thing about the Needwood Forest torc, and which links it to other sheet gold torcs like Netherurd, the Snettisham Great and Grotesque torcs, Clevedon etc, is that it has most likely been made using hammering and fusing, rather than casting, techniques. As such this – and the ‘Snettisham Style’ decoration – likely places its date at the earlier end of torc making in the Iron Age. Again, not certain, but definitely worth bearing in mind as we progress.

Summary

As ever, this up close experience with a torc has given me a lot of data and technological information to work with: last discussed in print in 1936, and with only a handful of poor quality images available prior to this work, this blog brings the Needwood Forest torc into the light. Thanks to the generosity of the Royal Collection Trust, we can all appreciate the joy that is the wonderful Needwood Forest torc.

Until next time.

…and you know the drill, if you want to keep up to date with the latest in the Staffordshire Torc Odyssey research, please click ‘Subscribe’ below.

Acknowledgements:

Huge ‘thank yous’ go to Hamish Bowie, George Easton, Emily Edwards, Lu Stanton-Greenwood, Hilary Harrison, Helen O’Connell, EikBrandr Solgyafi, Betty Lo, Rowan Taylor and Katie Hinds, who spent an afternoon checking my coil wire counts! The majority went for four wires in each coil!

I would also like to thank Bob Davies and George Easton for talking me through what they thought was happening with the torc terminals and wires. Having the benefit of their experience and knowledge is a wonderful thing, but all errors, omissions and interpretations are entirely mine!

Great images Tess, our efforts are nothing without the illustrations! Mary

LikeLike

Very much so!

LikeLike