by Tess Machling & Roll Williamson

[A download/print PDF version can be found at the end of the paper]

This paper can be cited as: DOI 10.5281/zenodo.10511424

Abstract

In our 2018 Proceedings of the Prehistoric Society paper (Machling & Williamson 2018) we discussed the manufacturing techniques of the Netherurd terminal, the Newark torc and suggested ideas regarding the Snettisham Great torc. Having furthered our research and – with a copy of the Snettisham Great torc x-radiograph now available in the public domain (Flynn 2017) – in this paper we update the evidence for the manufacturing methods of the known sheet torus torcs and detail our refined understanding of this technique, which has now been recognized in a number of torcs.

Introduction

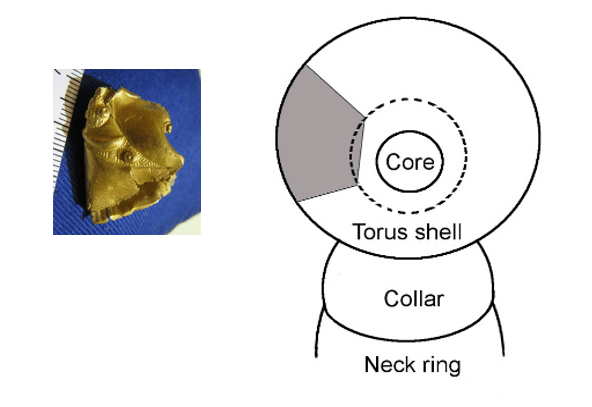

In 2015, we initiated our research into the manufacture of Iron Age gold torcs. Since that time we have published a number of papers, blogs and articles (Machling & Williamson 2016, 2017, 2018, 2019a, 2020a-c, 2022, 2023 etc) on the topic, detailing how many gold torcs, instead of being manufactured with the previously assumed cast-on terminals (see MacGregor 1976, pl.191; Eluère 1987, 34; Stead 1991, 454; Jope 2000, 253; Hautenauve 2004, 120–1; Cartwright et al. 2012, 26–7; Meeks et al. 2014, 150–51; Joy 2015, 41; La Niece et al. 2018), were in fact created from hand-worked sheet gold, using a three-part construction technique of a torus shell, core and collar (Fig. 1).

Background

Early on in our research, in August 2016 – and following our examination of the Netherurd terminal and discovery of the sheet construction technique – we asked the British Museum (email dated 15/6/16) if they had ever x-rayed the Snettisham Great torc. The Museum confirmed it had not been x-rayed as they were confident the terminals were cast, and that the ‘beam of the old [British Museum] equipment would not penetrate the thick gold’ (email dated 17/8/2016).

Knowing that Netherurd was sheet gold and having seen an x-radiograph of the sheet-made Snettisham Grotesque torc (on public display on the side of the Snettisham case in Room 50 of the British Museum, Fig. 2) we felt that, as the gold sheet terminals of the Great torc were likely to be thin, even a lower power x-ray might penetrate it. As such – but also with the benefit of the new, more powerful, 450kV x-radiography suite recently installed at the British Museum – in August 2016 we requested that the Great torc should be x-rayed.

The British Museum carried out this request in June 2017. We were not present but were later invited to the British Museum to view the x-radiographs – which clearly demonstrated the Great torc to be sheet and, as we’d predicted (Machling & Williamson 2016, 4), manufactured using the same tri-partite construction method seen in both the Netherurd and Grotesque torcs (Fig. 1).

Unfortunately, even though we had requested the x-radiographs to be taken, the images were, and remain, the copyright of the British Museum and they intended them to be published in the Snettisham volume (Joy & Farley, forthcoming). As such, we have been unable to reproduce, or discuss, them fully until that publication is released. This has hampered our research considerably.

However, recently we have been made aware that an image of the Snettisham Great torc x-radiograph has been available in the public domain since 2017 (Flynn 2017) and – with the Snettisham hoards volume repeatedly delayed – we feel it is appropriate, and timely, to discuss this image now.

Tri-partite torcs

The torcs (Table 1) that can be described as being made using this method can now be confirmed as the Netherurd terminal (Fig. 3), the Snettisham Grotesque (Fig. 6) and Great torcs (Fig. 14), the Near Stowmarket terminal fragment (Fig. 11) and the Clevedon torc (Fig. 10).

It is also likely that the recently auctioned Knaresborough Ring was cut from the collar of a decorated torus torc (Fig. 18). This ring will be discussed in detail in a later paper as its biography is complex and beyond the scope of this work. It is also likely that Torc L20 (British Museum accession number 1991,0407.38) is also a tri-partite sheet torc (Fig. 21). It should be noted that we have not yet been able to examine this torc in hand.

In addition to the recognizable tri-partite sheet torcs there is also a fragment of torc (British Museum accession number 1991,0501.7) with concentric circle decoration – only seen in gold alloy torus torcs – which is likely to come from a tri-partite torc (Fig. 22). As such, we have now recognized eight probable individual tri-partite constructed, sheetwork, gold alloy torcs.

The Newark torc (Fig. 25), however, as later work showed (Machling & Williamson 2020, 87) is not a sheet gold torc but – although conforming to the tri-partite form in having a torus, core and collar – rather a cast/hammered hybrid, with a cast torus terminal and collar and hammered sheet core. In addition, although not a tri-partite torc, the Snettisham Mini-Grotesque torc (British Museum accession number 1991,0501.45) merits mention as the form and sheet technique is related, although slightly adapted (Fig. 23). Each of these torcs is discussed below.

The Netherurd terminal

This terminal, being detached, was able to be examined intermally. What this demonstrated was that seams exist around the core and collar of the terminal and that the sheets may have been manually secured by pressing, or similar (Fig. 3). There are no obvious traces of solder on the joints, and joining by diffusion bonding or similar is possible.

An overlap between the core and the torus shell can clearly be seen in the right photo of Figure 3, with the core sheet lying outside the torus shell sheet (Fig. 1, right). On the exterior, the back of the terminal shows no sign of the overlap, with all trace having burnished away. On the front of the terminal, the circle of punched dots would seem to define the approximate edge of the core sheet – the dummy rivets, punched dots and tooled lines perhaps having been utilised to further compress the torus shell and core sheets together (Fig. 4).

At the point where the torus shell meets the collar, there is again evidence of a sheet overlap, in this case a ridge of alloy where the sheets appear to have been pressed together, or perhaps folded over (Fig. 5).

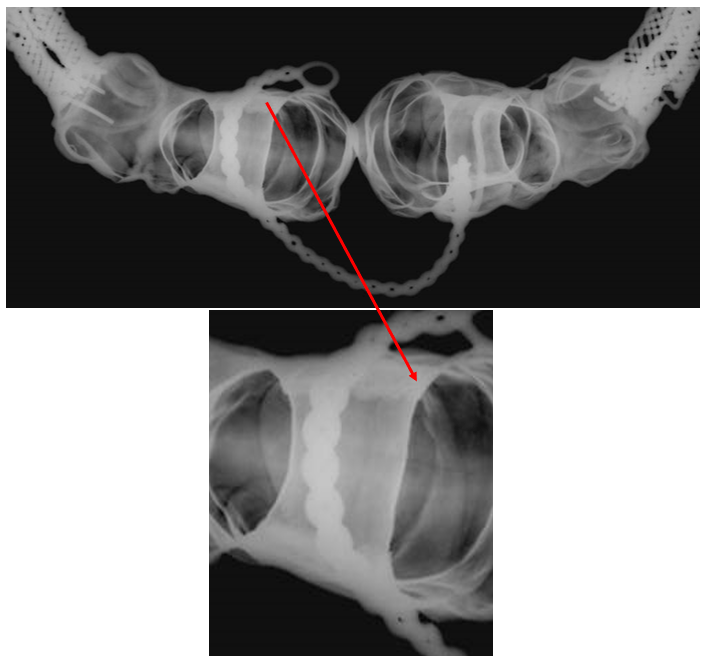

The Snettisham Grotesque torc

Similar to the evidence seen in the Netherurd terminal, the x-radiograph of the Grotesque torc (on public display in Room 50 of the British Museum) shows that the core overlaps the torus shell with the core sheet on the exterior (Fig. 7). A similar ridge of thickened gold alloy visible on the top and bottom of the core (a whiter band) of the Grotesque terminals in x-radiograph, corresponds with that seen on the interior of the Netherurd terminal (Fig. 3).

This overlap has again been burnished to leave no trace on the exterior although, it seems likely that, again, the circle of punched dots on the exterior terminal face delimits the line of the sheet overlap, with one section showing a hole (Fig. 8) where it is likely the sheets did not entirely meet. It is also likely that this circle of punched dots, as with the Netherurd dummy rivets, was used to help secure the join between the core and tors shell sheets.

This similarity of decoration and manufacturing method would further suggest a link between the apparently earlier and later torus torc forms (see Machling & Williamson 2023).

The Clevedon terminal

As discussed in a previous paper (Machling & Williamson 2019b) it is likely that the Clevedon torc terminal originated as a torus torc of Netherurd or Great torc type (Fig. 9). Again, on the interior (Fig. 10), the torc terminal shows evidence of a seam, between the collar and current neck ring ‘skirt’, which – viewed alongside the differing decoration on the face and collar – seems to relate to its origins as a tripartite constructed torus torc (see Machling & Williamson 2019b for further detail).

The Near Stowmarket terminal fragment

This fragment (Fig. 11), discovered in 1996, but only published in 2020 (Machling & Williamson 2020b) is the upper section of a cut down torus torc terminal, of similar size to that seen in Netherurd or the Snettisham Great torc (Fig. 14).

As a broken terminal piece the interior can be easily examined, and it once again confirmed the tri-partitie manufacturing technique, with the overlapping boundary of the torus shell and core sheets clearly visible (Fig. 13). Again it can be seen that the core sheet clearly overlaps the torus shell.

The Snettisham Great torc

As previously discussed, the release of the x-radiograph image in a British Museum newsletter (Flynn 2017) has allowed the discussion of the features shown in the x-radiograph of this torc. As the only torus torc of the ‘Snettisham style’ (Jope 2000, 84) to have been x-radiographed, this information is critical to our research.

The x-radiograph again shows the features identified in the Netherurd, Grotesque and Near Stowmarket torcs: a tri-partite manufacture, with torus shell, core and collar units, and again, with the core overlapping the torus shell on the exterior (Fig. 15).

Again, as with the Netherurd (Fig. 3) and Snettisham Grotesque torcs (Fig. 6), it would appear that the exterior decoration in the Snettisham Great torc core area has been utilised to help secure the joining of the core and torus shell sheets (Fig. 15).

There is also evidence that the core sheet may have been worked into the external ‘pie-crust’ decoration, with at least two areas (Fig. 16) on the terminal exteriors which, like the Grotesque terminals, features an incomplete join.

In addition to the clear evidence of overlapping sheet construction, close examination of the x-radiograph shows a series of nicks or cuts on the core margin (Fig. 17, left). This splay could be the product of the core sheet being cut to allow it to be closer fitted to the torus shell, or could be the natural result of overworking thin sheet which has not been correctly annealed (heated), which results in the sheet margins starting to crack (Fig. 17, right).

The Knaresborough Ring

This ring (Fig. 18) is the subject of an upcoming paper, which details the prolonged object biography of this intriguing artefact, and so will not be discussed in detail here. However, a brief summary of evidence for its origins as a torus torc terminal is given below.

The Knaresborough ring is made from sheet gold, about 0.5mm thick. This compares favourably to the c.0.7mm sheet thickness of torus torcs such as Netherurd and the Snettisham Great torc. In addition, the decorative elements are of similar form and size to those seen in torus torcs and the exteriorly worked uchidashi manufacturing technique (see Machling, Williamson & Hallam 2019) would also appear to be similar.

The recorded width of the ring bezel, of 25mm, would support such a theory, and compares well with the Snettisham Great torc collar height of 21.3mm and Clevedon of 17.5mm (Fig. 19). The full ring circumference (including tip-to-tip wire ring measurement) would result in a similar collar diameter to the c.32-34mm aperture diameter of known torus torcs, such as the Snettisham Great torc (Fig. 19) and the Netherurd terminal (Fig. 20).

In addition, the slightly asymmetric positioning of the wire ring in the Knaresborough example (Fig. 18) would suggest that the utilized panel (as in the Snettisham Great torc and Netherurd and Clevedon terminals, Figs. 19 & 20) rose at the front of the collar, tapering down to the base-edge of the torc collar on the sides. The folded edges seen on the ring (see PAS report BM-CDF17E) would conceal the cut edges. As such the ring would appear to represent a cut away panel of decoration, from the front of a torus torc collar, with the ring and closing hooks hammered into wire from the lower edge of the torc collar.

The L20 torc from Snettisham

This torc (Fig. 21) was found in Hoard L, towards the bottom of the deposit, and just below the Grotesque torc. This torc is highly unusual, being the only torus torc decorated with two-dimension techniques, the usual dummy rivets, lentoids and trumpets delimited in dots and punched lines, rather than in the usual high-relief features.

In addition, the torc terminal is larger than both the Netherurd and Snettisham Great torc terminals, with a proportionally smaller central hole than either. Although this torc has not been viewed by us in hand, we consider that it could be a torus torc that has been marked out ready for relief decoration, the larger terminal size necessary so that the gold could be knocked back, using the uchidashi technique (see Machling et al 2019).

However, there are several, similarly punch and line decorated – albeit buffer – terminal examples from North Norfolk, including Snettisham (British Museum accession numbers: 1992,1203.4 & 1991,0501.19) and Kings Lynn (PAS: NMS-D3BF38), which might suggest the L20 decoration was complete. It is also possible that the terminal was received by someone as an undecorated torus torc ‘blank’ which was then only simply decorated as the skills to achieve the 3D relief were not available to them. There are hints of such differing levels of goldsmithing skills from Snettisham already in the probable repair of the Grotesque torc (see Machling & Williamson 2020c).

Snettisham terminal fragment

This tiny piece of torc terminal, measuring only around 10mm across, is attached to several other broken piece in a small collected group. The sheet is c.0.7-1mm thick and is heavily abraded, with possible melted metal on the rear of the fragment. However, the presence of concentric circles – a decorative technique only seen in torus torcs – suggests that the fragment originated from such a torc. The additional worn linear striations/punching which surround the circles (see Fig. 22, left) would also support a torus torc origin for the piece.

Mini-Grotesque torc

The mini-Grotesque from Snettisham (Fig. 23) is the extreme of the sheet-working technique, with measurements approximately equivalent to the Newark torc terminals (44mm x 43mm x 15mm), and yet which weighs only 22g.

The terminal was created by the seaming of two torc shell halves with minimal dotted solder added to hold the two pieces together on the interior of the core (Fig. 24, left). However, on the exterior of the torus, the join is invisible. Only after the two shell halves have been joined was the collar added (Fig. 24, right). This method has only so far been identified in the Snettisham Mini-Grotesque torc.

Newark torc

In our 2018 paper (Machling and Williamson 2018) the Newark torc was identified as having sheet-worked gold terminals (Fig. 25). However, following a 450kV X-radiograph carried out at GE Inspection technologies in September 2018, it has been recognised that this interpretation was incorrect and that the torc terminals instead show a hybrid of casting and other techniques more often seen in sheet work/hammered torcs (Machling & Williamson 2020a).

Initially thought to be sheet gold, the September 2018 X-radiograph gave a much clearer picture of the torc and showed that the relief was not hollow on the interior, but solid, and revealed an internal flat profile to the terminal walls far more typical of casting (Fig. 26, left). However, it was also very clear that the terminal was not cast-on, but cast separately and then carefully finished before being joined to the wires.

The Newark torc, identical in size and form to the Sedgeford torc, has two obvious differences: it has seams running around the central core hole (Fig. 27) and a central aperture which is 2mm wider than that in the Sedgeford terminal. As mentioned above, the seam was initially thought to be indicative of sheet-work construction of the type seen in the Snettisham Great torc and the Netherurd terminal. However the X-radiograph (Fig.26, right) showed that this feature was in fact a ring of gold alloy, added to fill a deliberate gap in the vicinity of the torc core casting. This ring was probably added through the neck of the torus and then fixed before the collar was added.

This feature can be seen on both of the Newark terminals and has been executed so precisely that we believe it to be a deliberate constructional feature, rather than a repaired fault. The reasons for this addition appear twofold: firstly, this gap would have allowed access into the interior of the cast torus which might be of benefit during the decorating process and secondly, most importantly, as a means of preventing the torus from cracking during casting. This gap in the cast would have allowed room for contraction/expansion of the molten gold during cooling and so would prevent cracking of the type seen in the mis-cast Sedgeford terminals (Fig. 28).

In many torcs, including the Sedgeford torc and many of the Snettisham examples, evidence of casting cracks can be seen. These cracks have sometimes, as on the Sedgeford torc (Fig. 28), been intricately repaired using rivets and infilling gold. The cracking, and subsequent repair, can also be seen on other Iron Age cast items, for example horn-caps. However, the Newark torc terminals are unique amongst all other known hollow cast terminals in that there are no cracks or faults in either terminal.

We propose that for the Newark torc the mould was deliberately made in such a way that it created a gap in the casting of the torus to circumvent the problems seen on other torcs and that this unusual method indicates two very different levels of torc goldsmithing in the British Iron Age: with craftspeople highly skilled in a range of gold-working techniques using them to produce precision gold-work in both sheet and cast techniques (e.g.Netherurd and Newark) and those, less skilled, who could produce cast torcs, albeit faulty ones (many of the East Anglian torcs).

It would appear that casting was being used to mimic sheet-work torcs. But it also seems that the casting technique could have been utilised by skilled goldsmiths, versed in both sheet and cast working, when gold alloy quality was insufficiently pure to allow for sheet-working (e.g. in the Newark torc) or, perhaps in the case of the East Anglian torcs, when the sheet-working skills needed to carry out a Netherurd/Great torc style terminal were not present (perhaps had never been present?) in a region and so casting became the only option available (Machling and Williamson 2018, 400). Recent work has suggested that these differences may be the result of different dates of torcs, with sheet work torcs appearing earlier, and cast later (Machling & Williamson 2023).

Summary

This paper has gathered together the eight currently known probable sheet made, tripartite, torus torcs. Traditionally assumed to be East Anglian in origin (Meeks et al. 2014, 154; La Niece et al. 2018, 415), the locations of these torcs (four from Norfolk, one from Suffolk) would initially appear to support this claim.

However, the four Norfolk examples originate from one site: Snettisham, the hoards of which site are thought to result from the localized curation of torcs which originated from disparate parts of Britain (Machling & Williamson 2023). As such, the presence of tripartite sheet gold torcs from what is now Scotland, Somerset and – probably – Yorkshire would suggest a far more widespread origin. If the Newark torc, which relates to the tripartite torcs both technologically – and to Netherurd in decoration (see Machling & Williamson 2018) – is included, an origin for sheet working in this form should be sought beyond East Anglia to the north and west of Britain.

Recent work (Machling & Williamson 2023) has suggested that the ‘Snettisham style’ (Jope 2000, 84) may be earlier than previously suggested, and may be yet another example of the localised evolution which occurred in goldwork across Europe from the early 4th century BC. As such, the eight torcs detailed may represent some of the earliest Iron Age gold work seen in Britain and Ireland.

References:

Cartwright, C., Meeks, N., Hook, D., Mongiatti, A. & Joy, J. 2012. Organic cores from the Iron Age Snettisham torc hoards: Technological insights revealed by scanning electron microscopy. In C. Cartwright, N. Meeks, D. Hook & A. Mongiatti (eds), Historical Technology, Materials and Conservation, 21–9. London, Archetype.

Eluère,C. 1987. Celtic gold torcs. Gold Bulletin 20, 22–37

Flynn, D. 2017. X-ray imaging of the Snettisham Great Torc. British Museum Scientific Research Newsletter, 3. 1.

Hautenauve, H. 2004. Technical and metallurgical aspects of Celtic gold torcs in the British Isles (3rd–1st c. BC). In A. Perea, I. Montero & Ó. García-Vuelta (eds), Tecnología del oro antiguo: Europa y América [Ancient Gold Technology: Europe and America], 119–26. Anejos de Aespa 32. Madrid, Consejo Superior de Investigaciones Científicas, Instituto de Historia, Departamento de Historia Antigua y Arqueología.

Jope, M. 2000. Early Celtic Art in the British Isles. Oxford: Oxford University Press

Joy, J. 2015. Approaching Celtic art. In J. Farley & F.Hunter (eds), Celts: Art and identity, 37–51. London: British Museum Press.

Joy, J. & Farley, J. The Snettisham hoards, London. Forthcoming.

La Niece, S; Farley, J; Meeks, N & Joy, J. 2018. Gold in Iron Age Britain. In Schwab, R; Milcent, P-Y; Armbruster, B & Pernicka, E (eds), Early Iron Age Gold in Celtic Europe: Science, technology and Archaeometry. Proceedings of the International Congress held in Toulouse, France, 11-14 March 2015, 407-430. Rahden: Verlag Marie Leidorf GmbH

MacGregor, M. 1976. Early Celtic Art in Northern Britain. Leicester: Leicester University Press.

Machling, T. 2022. Pattern and purpose: a new story about the creation of the Snettisham Great torc. Blog. https://bigbookoftorcs.com/2022/05/29/pattern-and-purpose-a-new-story-about-the-creation-of-the-snettisham-great-torc/

Machling, T. & Williamson, R. 2016. The Netherurd torc terminal – insights into torc technology. PAST: The Newsletter of the Prehistoric Society 84 (Autumn 2016), 3–5.

Machling, T. & Williamson, R. 2017. ‘Up close and personal with Iron Age torcs!’, Later Prehistoric Finds Group Newsletter 10 (Winter 2017), 15-18.

Machling, T & Williamson, R. 2018. ‘Up Close and Personal’: The later Iron Age Torcs from Newark, Nottinghamshire and Netherurd, Peeblesshire. Proceedings of the Prehistoric Society. 84. 387–403.

Machling, T & Williamson, R. 2019a. ‘Damn clever metal bashers’: The thoughts and insights of 21st century goldsmiths, silversmiths and jewellers regarding Iron Age gold torus torcs. In C. Gosden, H. Chittock, C. Nimura & P. Hommel (eds), Art in the Eurasian Iron Age: Context, connections, and scale. Oxford: Oxbow.

Machling, T. & Williamson, R. 2019b. ‘”Cut and shuts”: The reworking of Iron Age gold torus torcs’, Later Prehistoric Finds Group Newsletter 13 (Summer 2019), 4-7.

Machling, T. & Williamson, R. 2020a. ‘Investigating the manufacturing technology of later Iron Age torus torcs’. Historical Metallurgy. 52, 2 (for 2018), 83-95.

Machling, T. & Williamson, R. 2020b. A rediscovered Iron Age torus torc terminal fragment from ‘Near Stowmarket’, Suffolk. Blog. https://bigbookoftorcs.com/2020/02/02/near-stowmarket-torc/

Machling, T. & Williamson, R. 2020c. Thoughts on the Grotesque torc and the Snettisham (Ken Hill) hoards in the light of new research. Independently peer reviewed blog: https://bigbookoftorcs.com/2020/09/22/thoughts-on-the-grotesque-torc/

Machling, T. & Williamson, R. 2023. Beyond Snettisham: a reassessment of gold alloy torcs from Iron Age Britain and Ireland. Forthcoming. Pre-print available: https://bigbookoftorcs.com/2023/06/23/beyond-snettisham-a-reassessment-of-gold-alloy-torcs-from-iron-age-britain-and-ireland/

Machling, T; Williamson, R. & Hallam F. 2019. ‘Going round in circles: the relief decoration of Iron Age gold torcs’. PAST: The Newsletter of the Prehistoric Society 93 (Autumn 2019), 3–5.

Meeks, N., Mongiatti, A. & Joy, J. 2014. Precious metal torcs from the Iron Age Snettisham treasure: Metallurgy and analysis. In E. Pernicka & R. Schwab (eds), Under the Volcano: Proceedings of the International Symposium on the Metallurgy of the European Iron Age (SMEIA), 135–56. Rahden: Verlag Marie Leidorf GmbH

Stead, I.M. 1991. The Snettisham treasure: Excavations in 1990. Antiquity 65, 447–64

One Reply to “”